1. What is thermoset? Give the examples.

It is one type of plastic which is require heat and pressure to mould the required shape.

2. What are design consideration for plastic manufacturing?

Avoid the undercuts, Avoid sharp corners, Provide shrinkage allowance, Locate the parting surface of the mould.

3. Mention the factors influencing the selection of plastics.

- Mechanical properties

- Degradation

- Wear resistance

- Cost

- Manufacturing methods

4. Compare thermoset and thermo plastic.

Thermo plastic

- Long, straight chained carbon

- Low strength

- Polyethylene

Thermoset plastic

- Cross linked compounds

- High strength

- Cannot be recycle

- Bakelite, epoxy

5. Define Elastomer.

It is nothing but a rubber. It is a polymeric material. It has large and reversible elastic deformation.

6. Define composite.

It is a material which is produced by combining two dissimilar materials for a better application.

7. What are the constituents of composites?

Matrix and reinforcing agent are the main constituent of the composite material.

8. What are the characteristics of composite manufacturing?

Light in weight, Good strength, Fire resistance, Wear resistance.

9. Mention any two composite materials.

Concrete, granite consisting of quartz, mica and feldspar.

10. What is pultrusion?

Pultrusion is an automated highly productive of fabrication of polymer matrix composite in the form of continuous long products of cross section.

11. What is degradation?

Brake down of chemical structure of plastic caused by heat stress and radiation.

12. What is calendaring?

It is the process of producing sheet of materials by rolling process.

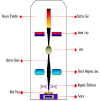

13. Sketch the calendaring process.

14. Describe about the structural foam.

Structural foam moulding process is used to make plastic products with a solid outer skin and a cellular inner structure.

15. Write the advantages of structural foam injection moulding.

Less cost, high strength, thick sections can be moulded, free foam shrinkage.

16. Enumerate three uses of the autoclave process.

Manufacture the turbine blades, Production of boats, Production of architectural moulding.

0 Comments

Write something...