1. Write the specification of milling machines.

Floor area, Net weight, Table length and type of machine.

2. Classify milling machines.

- Horizontal and Vertical milling machine

- Plano miller

- Universal mining machine.

3. Mention any four work holding devices in milling machine.

Machine vice, Angle Plate, Fixture, T bolt, V Block.

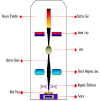

4. Explain about the spring collet.

- It is a tool holding device which is used to hold the milling cutter.

- The front portion of the device is tapered.

- and it is split by three equally spaced slots.

- Front end contains the cylindrical hole.

- The straight shank of the tool is palced inside this hole.

- The nut is provided in the tapered position.

- When it is screwed three jaws are closed. Then the tool shank is tightened.

5. List out the four types of milling cutters.

Side milling cutter, Angle Milling cutter, Dovetail and T slot cutter.

6. Describe indexing. List its types.

Indexing is the process of equally dividing the circumference of a circular work piece. Simple indexing and compound indexing are the types of indexing.

7. What is simple indexing?

- Simple indexing is a mechanism which is used to rotate the work piece as required.

- Selected indexing plate is fitted in the worm gear.

- Crank will be rotated as per the calculation.

- Bevel gear is used to transfer the angular motion to the work.

8. Name the gear finishing processes. (or) Name the finishing processes for hardened gears.

Gear burnishing, Gear Shaving, Gear grinding, Gear lapping

9. Write the advantages of the gear shaping.

- Single can be used for spur gear, helical and worm gears.

- Internal gears can cut easily.

- Rate of production is high.

10. List out the merits of gear hobbing.

- Multiple blanks can cut in a time.

- A single hob is used for all.

- Very fast production rate.

11. What are gear materials? (or) Give short notes on gear materials.

- The selection of gear material is depends on the manufacturing process, load, cost etc.,

- Cast Iron. Alloy steel, Nylon and Fiber are some of gear materials

0 Comments

Write something...