Pressure Lubrication system

The Pressure Lubrication system has

come into picture because the Splash Lubrication system is not suitable for

automobile engines due to the absence of positive lubrication.

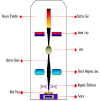

Components of Pressure Lubrication System:

- Crankcase (for oil storage)

- Oil Strainer

- Oil Pump

- Oil Troughs

- Crankshaft

- Oil Galleries

- Piston

- Cam Shaft

- Oil Pressure Gauge

- Oil Galleries

These

are in the form of pipes which serves the best lubrication compared to splash

lubrication system because here there is no case of leakage and the oil will be

passed to all the parts of the engine for better lubrication.

Working of Pressure Lubrication System:

- In this system, Oil is taken from the sump through the strainer by the pump and delivers it at a pressure of 4 to 6 bar to the main oil gallery.

- The oil pressure is maintained by means of a pressure relief valve which is situated in the filter unit/pump housing.

- The oil filter removes all the dust particles present in the oil and supplies clean oil to all the oil lines. The pressurized oil flows through the oil lines and galleries so as to lubricate the moving engine parts.

- Oil from the main gallery flows through the holes drilled inside the crankshaft and main bearing to lubricate them. The oil sprout connected with the gallery, forces the oil upwards to lubricate the piston and all the parts of it from inside.

- Oil

flows through the oil rings to lubricate and form a thin film around the

cylinder walls. After all the parts are lubricated in first gallery, the oil

will be pumped to the second gallery which can lubricate all the parts

connected with camshaft.

- The sprouts connected to the gallery helps in lubricating camshaft, valves and valve springs. After lubricating the engine parts, oil begins to flow downwards through a separate passage to the sump. A pressure gauge calculates the oil pressure in the system and displays it on the dial.

0 Comments

Write something...